LTC-503 is a fast, accurate, low-cost leak tester

LTC-503

The LTC-503 is Innomatec's latest advanced leak testing device designed for precise and reliable pressure testing across various applications. Built for efficiency and accuracy, it ensures seamless operation in industrial environments while supporting multiple test types. Its user-friendly interface and robust design make it an ideal solution for automated and manual testing setups. Designed for ease of use, the instrument simply integrates into the manufacturing line so you can start testing quickly.

- Pressure decay leak test

- Differential pressure leak test

- Vacuum leak test

- Flow & Mass Flow

Key Specifications:

- 4" color touch screen with dark/active mode

- One-touch start/stop button with illuminated RED/GREEN light

- Pressure vs time graphs with RED/GREEN test result status

- 200 editable programs with high/low limit settings

- Test pressure range: Vacuum to 20 bar positive pressure

- 5000 result storage (expandable) with screenshot capturing

- Interfaces: RS232, Ethernet IP, ProfiNet, Profibus, WiFi for remote service

- Serial Leak for automated lines

- Calibration Port

- Call for next test program- if OK/if NOK/Always/Never without PLC logic

- Configurable for multiple test ports with Bus system.

- Test pressure resolution X.XXXX Pa

- Pressure drop resolution X.XXXX Pa

- Leak rate resolution X.XXXX cc/min

- Internal & External venting options

- Used for Sealed component leak testing

Leak Simulator

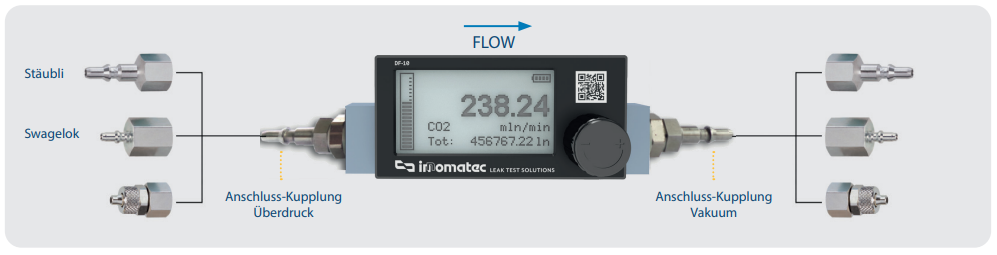

Ensure the reliability of your leak testing system with the innomatec DF-10 Leak Simulator. Designed for universal use across all industrial environments, the compact DF-10 delivers precise leak simulation in flow, unaffected by pressure and temperature variations. Combining ease of operation with innomatec’s renowned reliability, it’s the ideal solution for accurate and consistent testing.

- Models:

DF-10/50- Measuring Range: 0.6-50 cc/min

- Accuracy: ± 1.0% of full scale

- DF-10/500

- Measuring Range: 0.6-500 cc/min

- Accuracy: ± 1.0% of full scale

- Operating Temperature Range:

- 0-50 degrees Celsius

- Conditions:

- 0-95% RH, not condensing

- Power Supply:

- AA Battery or Micro-USB cable

- System Leak Rate:

- 1 x 10^-6 mbar l/s He

MHLS 100 – Turnkey Helium Sniff Leak Detection System

The innomatec MHLS 100 is a modular helium leak detection system designed to seamlessly integrate into your production line. Engineered for efficiency and precision, it simplifies the addition of sniffer leak detection, whether manual or automated, while reducing implementation time and cost.

Built on innomatec’s extensive experience in helium and forming gas testing, the MHLS 100 ensures reliable and repeatable results. Designed for industrial environments, it offers a streamlined solution to enhance your leak detection process with accuracy and consistency.

- Test Method: Helium/forming gas detection

- Test Connection: Single/multiple parts

- Test Pressure: 5 mbar – 16 bar

- Leakage Rate: 1 x 10⁻¹ to 1 x 10⁻⁵ mbar·l/s

- Detection: Manual (sniffer) / Automatic (robot)

- Operating Temp: 15-35°C, ≤50% humidity

- Options: Dual-pressure, test leaks, helium recovery

Features

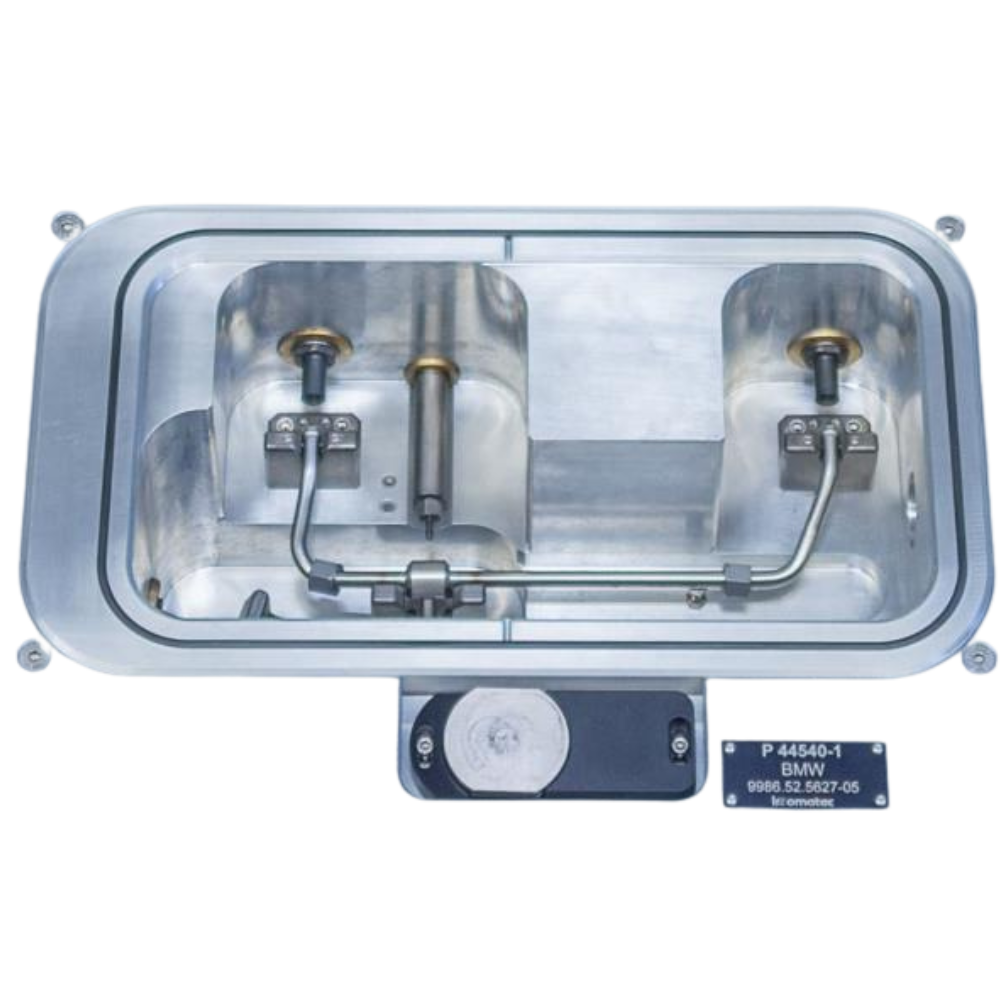

Helium Accumulation System

The innomatec Helium Accumulation System is a custom-engineered leak testing solution designed for precise and efficient detection of leaks in sealed components. Tailored to specific customer requirements, this system ensures highly accurate testing by accumulating and analyzing helium or forming gas escaping from the test part.

Internal Vacuum Leak Detection System

The Helium Accumulation System by innomatec is designed for high-precision leak detection in industrial applications. It ensures reliable testing for components across various sectors, meeting strict quality and safety standards.

- Test Method: Up to 700 bar against vacuum

- Detection limit: x 10⁻⁶ mbar*l/s

- Test Pressure: 5 mbar – 16 bar

- Cycle time: low as 36 sec/part

- Adaptation: Manual and automatic test piece adaptation

- Leak rate: 10⁻⁵ mbar*l/sec

- Sealing system: Manual and exchangeable sealing tools

- Chamber system: Quick-changeable helium chambers

- Changeover time: 5-15 minutes for new test types

- Recovery system: Integrated helium recovery

- Operation mode: Alternating and continuous testing

Features