In-process testing and monitoring solutions for quality 4.0 manufacturing

In-process testing and monitoring solutions for quality 4.0 manufacturing

In-process testing (IPT), or in-process verification (IPV), is a proven methodology of critical-to-quality operations on a part as it is being manufactured. Using Sciemetric Industry 4.0 systems, you will catch product defects before they leave the production line, reducing costly scrap and wasted cycles.

Sciemetric’s in-process test and monitoring systems can be applied to nearly any test on your line, including crimp, dispense, press-force / press-fit, leak testing, noise and vibration and harshness testing (NVH), welding, functional testing, profile inspections, torque testing, and more. Our data management and industrial analytics software well help you realize use the data from your test stations to realize the benefits of Industry 4.0. Report on quality, quickly analyze and address issues, improve cycle time and productivity, and more.

Contact UsIPT

Flexible, scalable solutions for in-process testing

sigPOD process monitoring system

sigPOD is Sciemetric’s out-of-the-box solution to enable in-process monitoring and testing to verify each part as it is assembled on the manufacturing line. This in-station process monitoring tool uses unique, advanced signature analysis technology to deliver reliable real-time pass/fail feedback with the most reliable defect detection. Its compact design and selection of pre-configured tests make it quick and easy to integrate on the line.

Learn More

Data collection and Industry 4.0 manufacturing analytics

Sciemetric’s data collection and manufacturing analytics solutions deliver everything manufacturers need to access the benefits of Industry 4.0. QualityWorX and Sciemetric Studio work together to provide data collection and organization and in-depth data analysis and reporting. Manufacturers have used these solutions to gain insights to quickly identify product quality problems in real-time, make informed decisions, provide proof of quality and more on their production lines. on your line.

Learn MoreOne standard solution for automated defect recognition & analysis across your production line

“Check where you can use our IPT Solutions across your manufacturing assembly process”

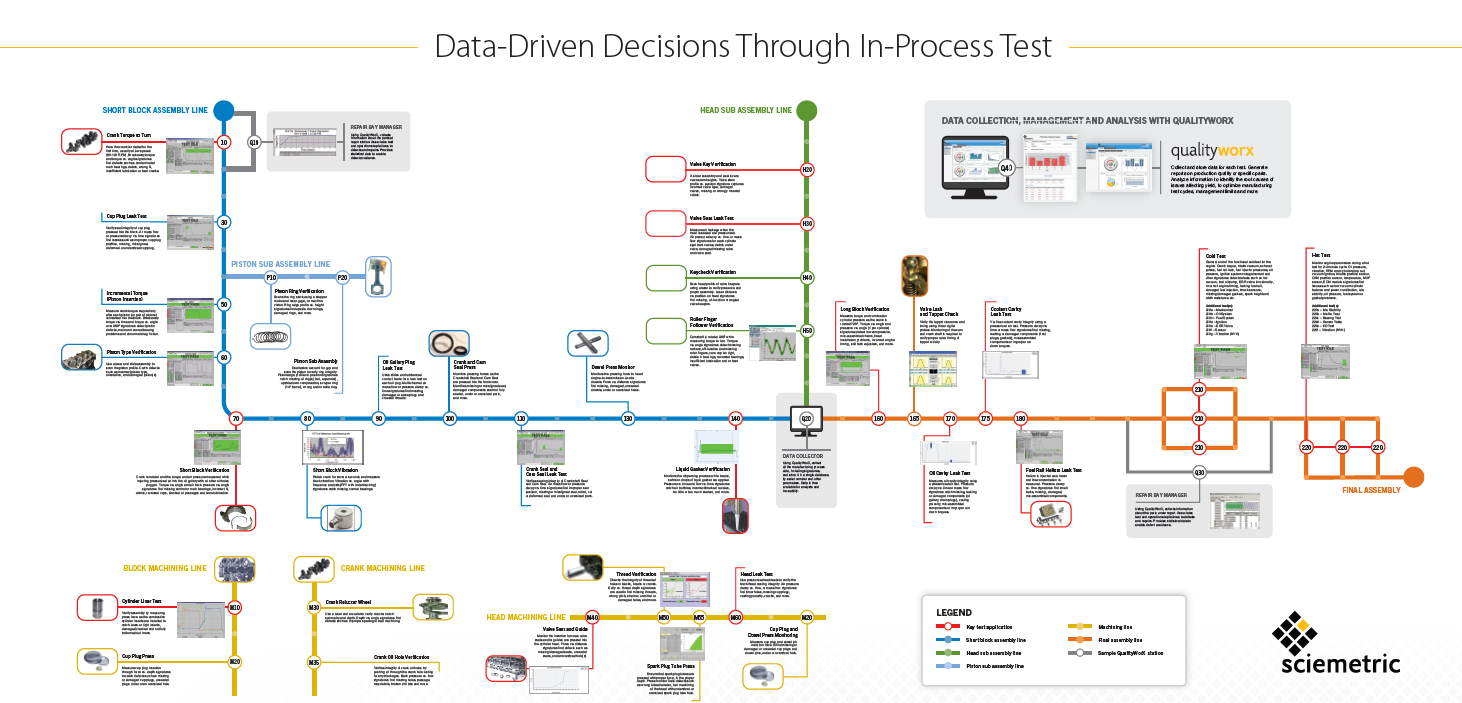

Make Data-Driven Decisions through In-Process Testing using DAQ and Analytics Solutions. From torque to turn to press-fit monitoring, we cover all functional process testing and monitoring in your assembly to detect defects and optimize downtime.

Download the IPT Engine Blueprint as an example for an ICE engine line and harness the combined power of in-process testing and data analytics on your production line.

View IPT Blueprint

The most accurate manufacturing defect detection, powered by digital process signatures technology

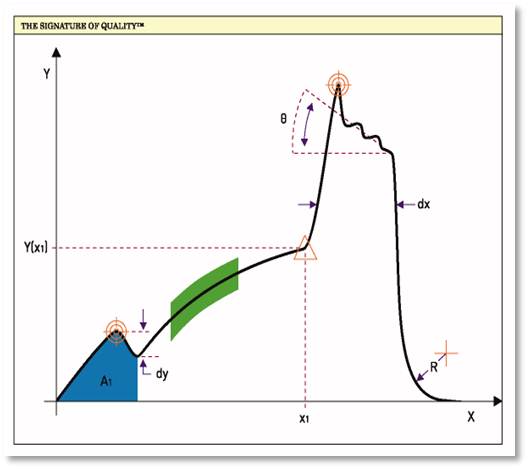

The sigPOD uses unique digital process signature technology to deliver the most accurate defect detection on the market. Most in-process test or monitoring systems rely on only a few points of measurement to identify a pass/fail, but the sigPOD measures hundreds or thousands of datapoints for a more accurate recording of the process. Our tools then apply complex algorithms to analyze this data to catch even the smallest deviations that could lead to product defects.

Overlay, analyze, visualize digital process signatures (or waveforms) to view trends across stations or focused on a single part (identified by serial number). Our technology helps you identify the root cause of defects, access insights to improve test limits, adjust cycle times and moreusing precise data rather than guesswork.

Speak to our Process Data SpecialistSmarter Manufacturing with Sciemetric Analytics

Harness the full potential of manufacturing analytics with Sciemetric’s turn-key manufacturing execution system. Capture, manage and trace real-time data at any process level, be it torque tools, leak tests, or presses for rapid root cause analysis.

Visualize trends and set alerts with our specialized Sciemetric Studio software and perform in-depth analytics of the data to ensure quicker resolution and enhanced problem solving with continuous improvement. Streamlining data collection to process monitoring transforms your manufacturing unit into an automated connected system with our tailored and advanced manufacturing analytics tools.

Check our analytics solutions